Industry knowledge

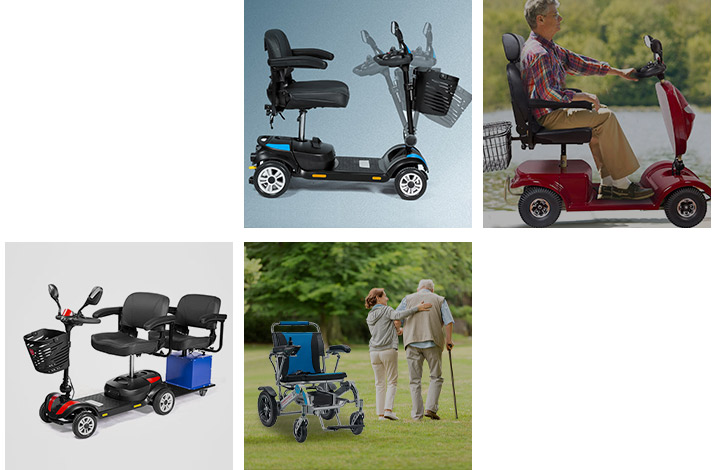

What is Aluminum Alloy Electric Wheelchair

An

aluminum alloy electric wheelchair, also known as a power wheelchair, is a mobility device designed to assist individuals with limited mobility in moving around independently. It is propelled by an electric motor and is typically controlled using a joystick or other control mechanisms. Here are some key features and characteristics of aluminum alloy electric wheelchairs:

Frame Material: Aluminum alloy is a common material used in the construction of electric wheelchairs. It is lightweight, yet strong and durable, making it suitable for mobility devices. The use of aluminum alloy helps to keep the overall weight of the wheelchair manageable while maintaining structural integrity.

Electric Motor: Electric wheelchairs are powered by rechargeable batteries and feature an electric motor that drives the wheels. The motor provides the necessary propulsion to move the wheelchair, reducing the physical effort required by the user.

Joystick Control: Most electric wheelchairs utilize a joystick control system that allows the user to maneuver the wheelchair in different directions. The joystick is typically mounted on one of the armrests and can be operated with minimal effort, providing smooth and precise control over the wheelchair's movement.

Battery System: The wheelchair's rechargeable battery system powers the electric motor. The battery is usually located beneath the seat or integrated into the wheelchair's frame. The capacity of the battery determines the range (distance the wheelchair can travel on a single charge) and may vary depending on the specific model.

Adjustable Seating: Electric wheelchairs often feature adjustable seating options to provide comfort and accommodate different user preferences. The seat height, depth, and angle can usually be adjusted to ensure proper positioning and support for the user.

Safety Features: Electric wheelchairs come equipped with various safety features to ensure user safety and stability. These may include anti-tip wheels, seat belts or harnesses, and braking systems that allow for controlled stops and prevent the wheelchair from rolling unintentionally.

Mobility and Terrain Capability: Electric wheelchairs are designed for both indoor and outdoor use. They are typically equipped with wheels suitable for various terrains, including solid flat surfaces, carpeted areas, and outdoor paths. Some models may have larger wheels or additional features to handle rougher terrain or obstacles.

Portability and Transport: While electric wheelchairs are generally heavier and bulkier compared to manual wheelchairs, many models offer features that facilitate transport and storage. Some wheelchairs have folding frames or removable components to make them more compact and easier to transport in vehicles.

Accessories and Customization: Electric wheelchairs often have accessory options to enhance user convenience and comfort. These may include features like adjustable armrests, headrests, leg rests, and specialized seating cushions. There are also options for attaching bags or baskets for storage purposes.

The production steps of Aluminum Alloy Electric Wheelchair

Here is a general overview of the typical production process:

Design and Planning: The manufacturer designs the

aluminum alloy electric wheelchair, considering factors such as ergonomics, functionality, safety standards, and user requirements. This involves conceptualizing the design, creating 3D models, and finalizing the specifications.

Material Selection: Aluminum alloy is chosen as the primary material for the wheelchair frame due to its lightweight, strength, and corrosion resistance properties. The manufacturer selects the appropriate grade of aluminum alloy for the frame components.

Frame Fabrication: The aluminum alloy frame is fabricated using various manufacturing techniques such as cutting, bending, welding, and CNC machining. Computer-controlled equipment ensures precise fabrication and accurate assembly of the frame components.

Motor and Electrical Components: The electric wheelchair requires a motor and electrical components for propulsion and control. These components are selected based on the desired performance and features of the wheelchair. The motor is typically mounted near the rear wheels, and the electrical components are integrated into the wheelchair frame.

Seat and Upholstery: The seat and upholstery of the electric wheelchair are manufactured separately and then attached to the frame. The seat is designed to provide comfort, support, and adjustability for the user. The upholstery is typically made of durable and easy-to-clean materials.

Battery and Control System: The electric wheelchair is equipped with a rechargeable battery and a control system. The battery powers the motor, while the control system allows the user to operate the wheelchair using buttons or a joystick. The battery and control system are integrated into the wheelchair frame, typically under the seat.

Quality Assurance and Testing: Once the wheelchair is assembled, it undergoes rigorous quality assurance checks and testing. This includes verifying the performance of the motor, electrical components, control system, and safety features. The wheelchair is tested for functionality, stability, durability, and compliance with industry standards.

Finishing Touches: The wheelchair goes through a final inspection and any necessary adjustments or fine-tuning are made. The manufacturer may add branding, labels, and user instructions to the wheelchair. The wheelchair is then cleaned and prepared for packaging and shipping.

Packaging and Shipping: The aluminum alloy electric wheelchair is carefully packaged to protect it during transportation. It is then shipped to distributors, retailers, or directly to customers, depending on the manufacturer's distribution model.